Fields of competence

ROBOTNOR represents a unique synergy of academic and industrial expertise which allows us to counsel and comprehend a wide variety of tasks and projects. Our fields of competence are numerous and diverse.

There has been a lack of suitable grippers that can handle non-rigid objects such as fresh meat (meat portions) from land animals and fish (fish fillets or portions). Such non-rigid objects often vary in shape, size and texture and cannot be handled with conventional robot grippers as two-jaw grippers or similar, developed for handling rigid material.

Researchers at SINTEF Raufoss Manufacturing have during last years developed new gripper solutions for handling non-rigid objects.

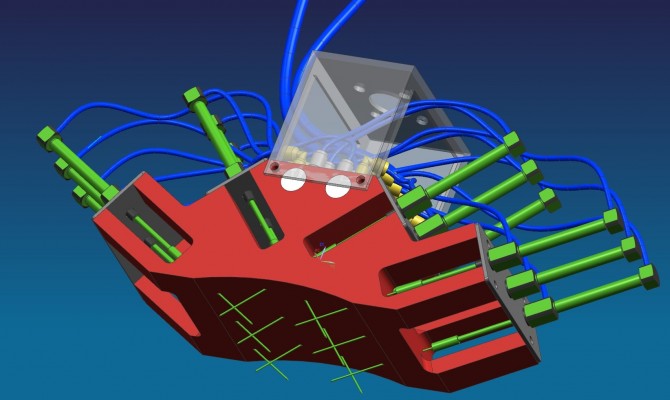

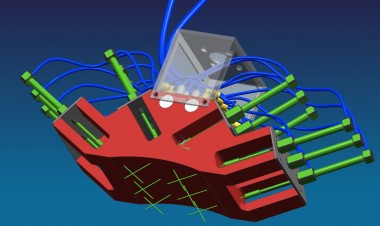

Needle gripper with crossing needles (patented)

The needle gripper has a rigid contact face against the object and a suitable number of needles made of stainless steel. The gripper body is made of polyethylene. Small pneumatic cylinders move the needles in a lengthwise direction between an extended and a retracted position. Each pair of needles creates a cross inside the piece of meat (or other penetrable object). The needle gripper with crossing needles gives a good hold between the gripper and the non-rigid (penetrable) object.

Figure 1 Needle gripper with crossing needles.

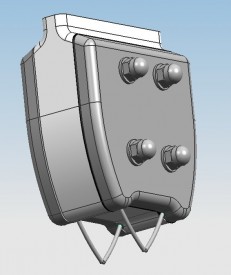

Compact needle gripper

The prototype of the compact needle gripper has two pairs of needles. Also this gripper solution has a rigid contact face against the object and needles that penetrate the non-rigid object. These needles do not create a cross inside the object. Needles are curved and needle ends pairwise meet each other in extended position. The prototype solution has a hygienic design as required in the food processing industry. Since this gripper has a compact design, the gripper can be used for rather small objects (e.g. small portions of fish fillets).

Figure 2 Compact needle gripper

Freeze gripper with mechanical release

This gripper solution is equipped with a metallic (stainless steel) gripping area called freeze pad. These freeze pads are connected to a low-temperature circulating fluid that keeps it cold as long as necessary for a good grip. The objects (portions of fish or meat) have to be wet. To obtain a good gripping action the gripper’s freeze pad is pressed against the object. If there is a sufficient low temperature on the freeze pad there will be an immediate formation of ice in the contact area. The thin ice layer binds the object to the gripper. The release mechanism consists of a frame of stainless steel with a knife section that moves across the contact surface (the pad) when the frame is rotated by a pneumatic solution integrated inside the gripper. Then the object is released from the gripper. The knife will scrape the ice film off the freeze pad and then the gripper is ready for a new gripping action.

Figure 3 Freeze grippers with mechanical release mounted on a bracket

Testing of new gripper solutions

A lot of tests have been carried out in laboratory where robot equipped with needles grippers and freeze gripper have handled pieces of salmon, cod and pollock. Test show promising results. Handling with maximum acceleration up to 2.5 m/s² with needle grippers seems to create no observable damage to the meat issue. The needle gripper with crossing needles gives an even better hold between the gripper and the non-rigid objects than the compact needle gripper. The tests show that the freeze gripper gives a good hold when a thin ice layer is created in the contact area (freeze pad). Also meat portions of land animals have been tested with promising results.